Best natural products. Real variety. From Bad Wimpfen.

Quality is our ultimate goal and is the focus of our daily activities. This requires the conscious commitment and active cooperation of everyone involved. Motivated and qualified employees lead the way. A certified quality and energy management system, state-of-the-art mill technology, and years of experience are indispensable pillars for maintaining quality. For us, acting in a quality-conscious manner also means using valuable resources efficiently and sparingly.

Our quality promise - right from the start

Trust is good - the control of all incoming raw materials nevertheless goes without saying. Random samples are automatically taken from each delivery for testing by our sample tester. Raw materials are stored and released for production only if they meet the criteria of being sensory and chemically flawless.

The products also pass through significant stages of quality control, during grinding and packaging. They are only released when the requirements regarding the set quality parameters, but also regarding legality and safety, are met. To confirm this, we also have our products regularly analyzed by independent laboratories for a wide range of parameters.

The clear labeling of each product makes it possible to record exactly when it was produced and to which customer it was delivered. This ensures complete traceability from the raw material to the customer - another indispensable pillar for guaranteeing our quality.

About us

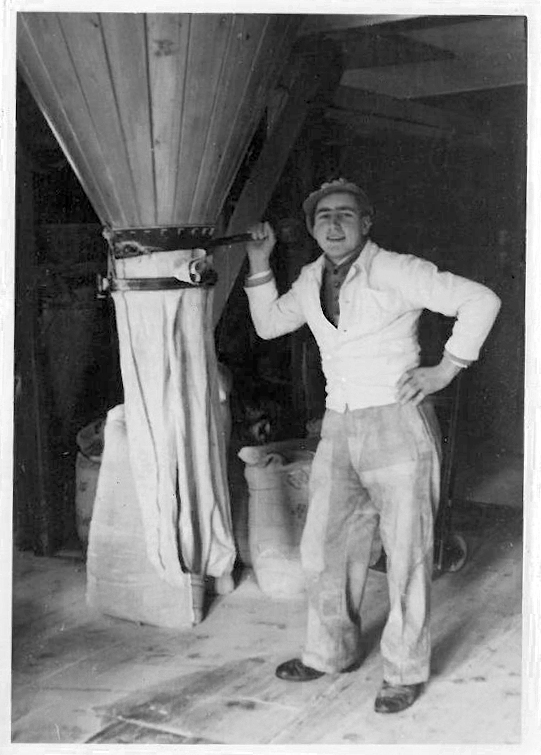

The Frießinger Mill was founded in 1859 by Johann Jakob Frießinger. After the death of our senior boss in December 2021, today Willi Frießinger leads the successful and tradition-conscious family business alone in the 5th generation. His children Willi Erich and Lisa Frießinger have joined the management team and will continue the family history in the 6th generation.

Mill tradition for over 160 years

From field to bread

Mills are the place where grain is turned into foodstuffs such as flour, bran, meal and other mill products. Every employee bears a great deal of responsibility in this process: starting with grain acceptance at our laboratory, through the complex milling process, to final product inspection and delivery.

Below you can find out which stations the grain has to pass through in compliance with the strictest quality criteria before it reaches our customers' hands as a high-quality product.

Grain cultivation and harvest

Raw material incoming inspection

Grinding process

Seven

Filling

Final inspection

Delivery

Pizza School

In addition to the classic grinding, mixing and convenience products, we also offer a wide range of special products in the field of pizza production. Here we have been working together with Umberto Napolitano's Pizza School for many years. He is well known from radio and television as well as the founder of the national pizza team and former pizza acrobatics world champion.

Special products for the production of extraordinary, fluffy-light, crispy-crunchy or rustic-tasty pizza doughs according to the traditional Italian model are not only produced by us, they can also be learned directly on site in pizza seminars. The courses are suitable for professional pizza makers as well as for those who want to become one! Immerse yourself in our world of pizza baking!

Sustainable towards the future

We want to offer our customers consistently high quality, which includes not only product safety but also a responsible approach to the environment. The focus here is on sustainable action towards people and nature. Thus, a careful handling of resources takes place, which is oriented towards future developments and generations.

Energy efficiency as a lived responsibility

Processing of the whole grain with all its by-products

Own port with connection to international waterways

Regional producers - maximum transparency and short transport routes

Compliance

The topic of compliance is also anchored in the corporate policy of Frießinger Mühle. Because legally compliant and fair conduct is a matter of course for us. We also demand this from our suppliers and business partners in order to ensure that human rights and environmental standards are observed along the value chain and that child labor, corruption and discrimination are prevented.

Whistleblower Protection Act

The primary purpose of the so-called whistleblower law is to ensure better protection for whistleblowers. The employee is usually the first to notice errors or grievances and can ensure that violations of applicable law are reported, uncovered, investigated and stopped. Employees, but also our customers or partners, have the opportunity to provide information in various ways (by name or anonymously). By telephone, by mail or by e-mail, both to external parties (e.g., the Federal Office of Justice) and to our internal reporting office (compliance@friessinger-muehle.de).